Attività di Manutenzione e Soccorso Industriale

Maintenance activities and Industrial Rescue

Adriano Paolo Bacchetta - Studio Consulenze Industriali Dott. Ing. Adriano Paolo Bacchetta

(in lingua inglese)

Maintenance services are often called upon to operate in high-risk environments and, for this reason, it is essential to identify the correct operating methods and methods of responding to a possible emergency situation.

Maintenance services, everywhere, are called to guarantee the smooth and efficient working of the industrial plant, and maintenance management helps in improving productivity and keeping the machines/equipment in their optimum operating conditions.

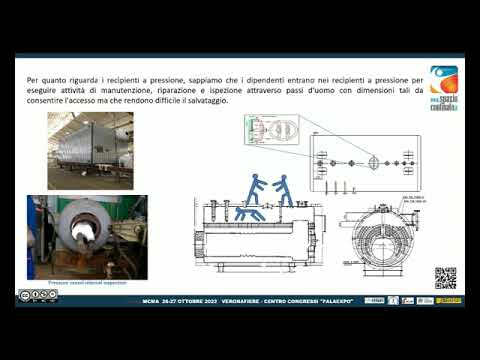

Maintenance in general is an important and inevitable service function of an efficient production system. In many maintenance activities, the works to be performed are planned in Confined Spaces. Around the World and, obviously also in Europe, we can find many places with Confined Spaces. Many industry sectors carry out work involving Confined Spaces, and most industrial facilities have Confined Spaces. Overall, the first goal must be to check if it is possible to avoid entering a Confined Space.

Since this is the best policy, any time is suitable to check if entering is inevitable, or if a Confined Space could be modified so that entry becomes unnecessary and/or work should be done from outside. Working in a Confined Space holds many hazards, for example:

- limited means of entry and exit

- poor oxygen

- the presence of toxic fumes and vapors

- electrical risks

- ... and many others

that pose serious risks to workers and fatalities could happen unexpectedly.

Fatalities in Confined Spaces happen in no time, during seemingly innocuous situations: inhaling an atmosphere that contains no oxygen causes loss of consciousness in a matter of seconds.

Often the hazard is not present at the time of entry, which reinforces the need for continuous monitoring and supervision of work in Confined Spaces, and a half or more of all workplace Confined Space fatalities involve workers trying to rescue their colleagues. If entering a Confined Space is performed, risk assessment results must be used to identify the precautions needed to avoid or to reduce to a minimum the risk of injury and the Employer has to make sure that the safe system of work, including the precautions identified, is developed and put into practice.

Everyone involved will need to be properly trained and instructed to make sure they know what to do and how to do it safely. Furthermore, adequate emergency arrangements must be put in place before the work starts. Emergency management, whatever its origin, is a particularly important aspect that requires a specific commitment by HSE managers.

The Employer must put an emergency response plan in place to ensure the safety and health of Employees during critical emergency operations. To do this, it is necessary to have to equip the organization with rescue and emergency training services that must be tight for the specific emergencies predictable depending on the business activities.

The responders must be qualified on-site Rescue/Standby teams and be able to perform:

- High-angle rescue/above-ground activities

- Confined Spaces rescue

- Trench rescue

- Fall protection rescue

- Remote locations and difficult work locations rescue

All workers involved as First Responders, must receive specific training through specific courses. In the case of fire prevention, training courses must be related to the type of activity and the workplace level of fire risk (low risk, medium risk, or high risk). In case of a health-origin emergency, it is necessary to highlight the specific limits of the planned intervention by a certified responder that, in the workplace, is normally in line with the concept of proper first-aid services according to the Community Directives.

First aid is the immediate application of first-line treatment following an injury or sudden illness, using facilities and materials available at the time, outside the EU, we can also find a specific sanitary responder called Industrial Paramedic, that is a clinical practitioner in paramedicine, with an expanded scope of practice, that uses his skills and expertise to provide emergency response, medical assessment, primary health care, chronic disease management, injury prevention, health promotion, medical referral and coordinate emergency medical evacuations as needed for Workers.

Normally, Industrial Rescuers are not paramedics and their designation must take into account their capabilities and conditions regarding their health and safety as well as the dimensions and specific risks of the company or production unit.

That said, it remains to define what is the minimum level of preparation for emergency management (Preparedness) and reaction capacity (Response) required to ensure the effectiveness of the intervention in particular areas, such as Confined Spaces. Industrial emergencies management involves the intervention of trained Employees with specific technical - technical / health skills and proven experience in the rescue field with the ability to plan, coordinate, and direct rescue operations yielding from multi-factorial emergencies, with particular reference to the assistance and rescue activities of an injured person or a person taken ill.

Among the various professional figures that relate to rescue activities in the industrial sector, beyond the institutional role of the Fire Brigade and the Urban Search and Rescue teams which perform a multiplicity of activities and hire their work in specific conditions mostly deriving from maxi emergencies of natural origin (disasters such as earthquakes, floods, the collapse of buildings for other causes, etc.), over time it is more and more affirmed the need for specialists (as Industrial Rescuers) able to intervene in the event of accidents in specific anthropic contexts, particularly in the pharmaceutical, chemical, petrochemical industries, as well as many others.

The emergency management operations in these areas, however, must be carried out by suitably qualified personnel in the "Industrial Rescue" area, able to operate according to the principles of interoperability with the emergency structures of the operational realities in which they are called to intervene; this need surfaced because the in-house emergency services due to their characteristics, capacity and/or size, may not have the technical and/or first-aid competencies and operational rescue management ability to apply extrication techniques of the victim from places that are difficult to access.

Despite the great commitment in terms of staff training, often the companies are not able to cope with the varied aspects of emergency management for activities in Confined Spaces; for these special activities, a work procedure specifically aimed at eliminating or, where not possible, minimizing the risks inherent the planned activities must be adopted and effectively applied, including the possible phase of rescue and coordination with the emergency system of the National Health Service and the Fire Brigade. Internationally, these rescue professionals are identified as Industrial Search and Rescue (ISAR) operators, an acronym that represents the specialist evolution of the more well-known Urban Search and Rescue (USAR), and identifies the activities performed by those who, depending on their skills and abilities, operate in the specific field of Industrial Rescue.

In general, these professional figures also follow the example of what is already an established reality in the USA and other English-speaking countries and are entering the national context (which we can identify as industrial rescuers and experts in industrial rescue) and they do not affect what is specified by national regulations in terms of role, competences and relative training.

The evolution of the needs of the maintenance/production sectors and, at the same time, the obligation for a high level of health and safety workers' protection, solicit the identification of operational tools that can univocally characterize the "recognizability" of the professionals prepared to operate in high-risk environments, for which specific physical qualities are required in addition to managerial/organizational, technical and health skills.

This "new" professional profile must be outlined in terms of role, tasks, and work experience, considering the heterogeneity and complexity of the different organizations, setting the goal of identifying the requirements in terms of knowledge, skills, and ability for different professional levels that can be called to operate in emergency conditions.

The figures of Industrial Rescuers and Expert in Industrial Rescue, are currently devoid of specific EU regulations and, for now, it is certainly necessary to develop a new professional profile compliant with the European EQF Framework, which defines their competencies, knowledge, skills, and experience such as to enable them to operate effectively in the industrial rescue operations. This classification is not simple because we are thinking about a professional profile that needs specific technical skills (rope progression, extrication and rescue techniques, etc.) but also good personal health conditions related to extra rescue efforts necessary during rescue activities.

Maintenance in general is an important and inevitable service function of an efficient production system. In many maintenance activities, the works to be performed are planned in Confined Spaces. Around the World and, obviously also in Europe, we can find many places with Confined Spaces. Many industry sectors carry out work involving Confined Spaces, and most industrial facilities have Confined Spaces. Overall, the first goal must be to check if it is possible to avoid entering a Confined Space.

Since this is the best policy, any time is suitable to check if entering is inevitable, or if a Confined Space could be modified so that entry becomes unnecessary and/or work should be done from outside. Working in a Confined Space holds many hazards, for example:

- limited means of entry and exit

- poor oxygen

- the presence of toxic fumes and vapors

- electrical risks

- ... and many others

that pose serious risks to workers and fatalities could happen unexpectedly.

Fatalities in Confined Spaces happen in no time, during seemingly innocuous situations: inhaling an atmosphere that contains no oxygen causes loss of consciousness in a matter of seconds.

Often the hazard is not present at the time of entry, which reinforces the need for continuous monitoring and supervision of work in Confined Spaces, and a half or more of all workplace Confined Space fatalities involve workers trying to rescue their colleagues. If entering a Confined Space is performed, risk assessment results must be used to identify the precautions needed to avoid or to reduce to a minimum the risk of injury and the Employer has to make sure that the safe system of work, including the precautions identified, is developed and put into practice.

Everyone involved will need to be properly trained and instructed to make sure they know what to do and how to do it safely. Furthermore, adequate emergency arrangements must be put in place before the work starts. Emergency management, whatever its origin, is a particularly important aspect that requires a specific commitment by HSE managers.

The Employer must put an emergency response plan in place to ensure the safety and health of Employees during critical emergency operations. To do this, it is necessary to have to equip the organization with rescue and emergency training services that must be tight for the specific emergencies predictable depending on the business activities.

The responders must be qualified on-site Rescue/Standby teams and be able to perform:

- High-angle rescue/above-ground activities

- Confined Spaces rescue

- Trench rescue

- Fall protection rescue

- Remote locations and difficult work locations rescue

All workers involved as First Responders, must receive specific training through specific courses. In the case of fire prevention, training courses must be related to the type of activity and the workplace level of fire risk (low risk, medium risk, or high risk). In case of a health-origin emergency, it is necessary to highlight the specific limits of the planned intervention by a certified responder that, in the workplace, is normally in line with the concept of proper first-aid services according to the Community Directives.

First aid is the immediate application of first-line treatment following an injury or sudden illness, using facilities and materials available at the time, outside the EU, we can also find a specific sanitary responder called Industrial Paramedic, that is a clinical practitioner in paramedicine, with an expanded scope of practice, that uses his skills and expertise to provide emergency response, medical assessment, primary health care, chronic disease management, injury prevention, health promotion, medical referral and coordinate emergency medical evacuations as needed for Workers.

Normally, Industrial Rescuers are not paramedics and their designation must take into account their capabilities and conditions regarding their health and safety as well as the dimensions and specific risks of the company or production unit.

That said, it remains to define what is the minimum level of preparation for emergency management (Preparedness) and reaction capacity (Response) required to ensure the effectiveness of the intervention in particular areas, such as Confined Spaces. Industrial emergencies management involves the intervention of trained Employees with specific technical - technical / health skills and proven experience in the rescue field with the ability to plan, coordinate, and direct rescue operations yielding from multi-factorial emergencies, with particular reference to the assistance and rescue activities of an injured person or a person taken ill.

Among the various professional figures that relate to rescue activities in the industrial sector, beyond the institutional role of the Fire Brigade and the Urban Search and Rescue teams which perform a multiplicity of activities and hire their work in specific conditions mostly deriving from maxi emergencies of natural origin (disasters such as earthquakes, floods, the collapse of buildings for other causes, etc.), over time it is more and more affirmed the need for specialists (as Industrial Rescuers) able to intervene in the event of accidents in specific anthropic contexts, particularly in the pharmaceutical, chemical, petrochemical industries, as well as many others.

The emergency management operations in these areas, however, must be carried out by suitably qualified personnel in the "Industrial Rescue" area, able to operate according to the principles of interoperability with the emergency structures of the operational realities in which they are called to intervene; this need surfaced because the in-house emergency services due to their characteristics, capacity and/or size, may not have the technical and/or first-aid competencies and operational rescue management ability to apply extrication techniques of the victim from places that are difficult to access.

Despite the great commitment in terms of staff training, often the companies are not able to cope with the varied aspects of emergency management for activities in Confined Spaces; for these special activities, a work procedure specifically aimed at eliminating or, where not possible, minimizing the risks inherent the planned activities must be adopted and effectively applied, including the possible phase of rescue and coordination with the emergency system of the National Health Service and the Fire Brigade. Internationally, these rescue professionals are identified as Industrial Search and Rescue (ISAR) operators, an acronym that represents the specialist evolution of the more well-known Urban Search and Rescue (USAR), and identifies the activities performed by those who, depending on their skills and abilities, operate in the specific field of Industrial Rescue.

In general, these professional figures also follow the example of what is already an established reality in the USA and other English-speaking countries and are entering the national context (which we can identify as industrial rescuers and experts in industrial rescue) and they do not affect what is specified by national regulations in terms of role, competences and relative training.

The evolution of the needs of the maintenance/production sectors and, at the same time, the obligation for a high level of health and safety workers' protection, solicit the identification of operational tools that can univocally characterize the "recognizability" of the professionals prepared to operate in high-risk environments, for which specific physical qualities are required in addition to managerial/organizational, technical and health skills.

This "new" professional profile must be outlined in terms of role, tasks, and work experience, considering the heterogeneity and complexity of the different organizations, setting the goal of identifying the requirements in terms of knowledge, skills, and ability for different professional levels that can be called to operate in emergency conditions.

The figures of Industrial Rescuers and Expert in Industrial Rescue, are currently devoid of specific EU regulations and, for now, it is certainly necessary to develop a new professional profile compliant with the European EQF Framework, which defines their competencies, knowledge, skills, and experience such as to enable them to operate effectively in the industrial rescue operations. This classification is not simple because we are thinking about a professional profile that needs specific technical skills (rope progression, extrication and rescue techniques, etc.) but also good personal health conditions related to extra rescue efforts necessary during rescue activities.

Fonte: temi tratti e proposti nel convegno Maintenance Webinar Confine Spaces organizzato da EHSC - EFNMS

Parole chiave: Service Manutenzione, Sicurezza industriale

English

English